September 1st, 2021. Rotterdam – Raise3D, the global provider of additive manufacturing solutions for SMEs and LSEs, announces the launch in late 2021 of the Pro3 Series, the most highly developed 3D printer of its segment, with improvements that address the needs of agile or small-batch production of end parts, tools, spare parts or other similar products.

The Pro3 Series includes two dual-extruder 3D printers: the Pro3, with a build volume of 300x300x300mm, and the Pro3 Plus, with a build volume of 300x300x605mm. Forged from the award-winner Pro2 Series, the Pro3 Series comes with improved usability, higher overall equipment effectiveness, and industrial-grade repeatability, making it the best choice in the segment for any customer using 3D printing in agile or small-batch production.

Raise3D Pro3 Series

In relation to material compatibility, the Pro3 Series is the printer with the broadest potential of its segment, capable of printing any filament that extrudes up to 300℃, including PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG, ASA, PP, PVA, Glass Fiber Infused, Carbon Fiber Infused, Metal Fill and Wood Fill, among others. Customers can expect top-quality results when using Raise3D filaments as well as 3rd party filaments that have been approved under the Open Filament Program.

The Pro3 Series printers are easily integrated into a production environment, since they connect with Raise3D’s 3D printing software ecosystem that includes the slicing software ideaMaker, the open-software template ideaMaker Library, and the print management software RaiseCloud.

Among the several new features, we highlight the following improvements:

Interchangeable Hotends

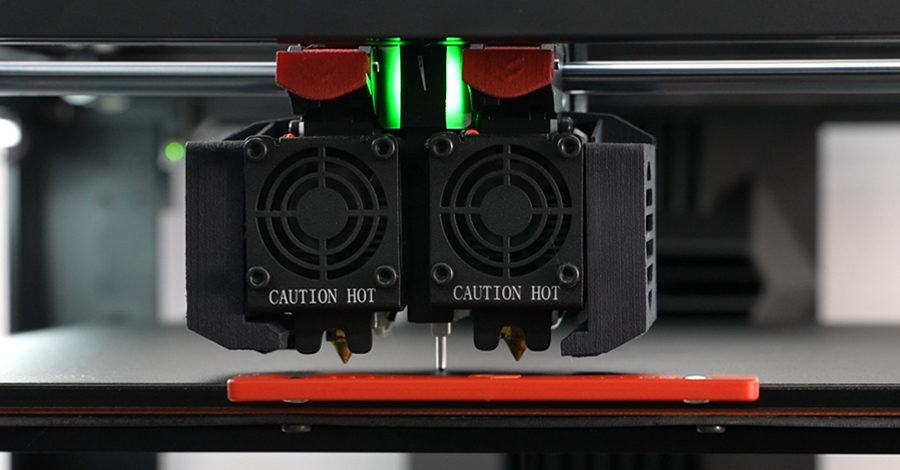

The Pro3 Series is equipped with an independent modular extruder with a dual-extrusion structure. This allows the Pro3 Series to print using a variety of filaments while reducing clogging, and enabling convenient disassembly and replacement of components, reducing machine downtime. The new interchangeable hotend system is ideal for users who may need to often switch from non-abrasive to abrasive materials that require different nozzle types, or users who want to print at higher speeds and require different nozzle sizes. They are designed with a click and lock mechanism that requires no tools, and each is uniquely identified in order track and record the nozzle usage time.

Interchangeable Hotends

Auto Bed Leveling

While Pro2 Series comes with a factory calibration that requires minimal or no calibration effort, Pro3 Series takes a step further in usability and comes with Auto Bed Leveling. The new Auto Bed Leveling feature is a relevant tool for those using printers for production purposes and who wish to implement a preventive maintenance program to ensure consistent quality of the final printed parts. Auto Bed Leveling minimizes the time allocated to calibration and increases productivity.

Auto Bed Leveling

Air Flow Manager

The Air Flow Manager of the Pro3 Series is located on the back of the printer, improving heat dissipation and air circulation, creating a stable environment inside the print chamber. Equipped with a HEPA air filter, Air Flow Manager can also filter and clean the air inside the chamber. As long as it operates within the recommended temperature range, the Air Flow Manager will ensure the stability of the temperature inside the chamber, which translates into better repeatability of top-quality results independently from the external conditions.

Air Flow Manager

EVE Smart Assistant

The Pro3 Series has a built-in smart assistant system known as EVE. Similar to what is common practice in 2D printing, the EVE assistant can guide users to accurately locate and resolve issues that might affect the final print job. It also has a function that analyses printer usage and sends users reminders of scheduled interventions to ensure that printer maintenance is performed on time.

Raise3D is the first company in its segment to introduce such a feature, bringing the usability of professional 3D printers to the next level.

EVE Smart Assistant

Other improvements

Among the other improvements, we highlight the following:

- Flexible build plate which allows an effortless removal of 3D printed parts.

- Z-axis rod stiffness increased by 75% to deliver more stable performance.

- Automatic Detection so that when a door is opened, that will immediately pause the print and resume it after the door is closed.

- Second-generation power-loss recovery, to save the printing status in the case of a power outage and continue printing from the same point after power is restored.

- Lightweight Cable with Digital Temperature Measurement.

- HD camera with enhanced image quality and exposure sensitivity.

Edward Feng, Raise3D global CEO, said “In 2018, when the Pro2 Series was first launched, we were committed to “Raise the Standards”, something that was acknowledged by the market with the attribution of relevant awards to our printers. As a result of the recognition of Pro2 Series, we started working on our mission: “To lead the promotion and implementation of Flexible Manufacturing Solutions with 3D Printing”. With the launch of the Pro3 Series, and the launch of the E2CF this year, we will confidently be “Implementing Flexible Manufacturing”.

Pricing and availability

The Pro3 Series launch is planned for late Q4, with the final date still to be set. Raise3D will be hosting an online public event later this year to present the new printer, while pre-sales will be opened a few weeks before the start of sales. The Pro3 Series 3D printer will also be showcased at Rapid+TCT in Chicago (Sep 13-15) and Formnext in Frankfurt (Nov 16-19).

Prices are still subject to change but are planned to be as follows:

|

|

USA and

Rest of the World |

Europe |

|

Pro3 |

5,249$ |

4,749€ |

| Pro3 Plus | 7,249$ |

6,249€ |

The Pro2 Series printers will be kept in the portfolio and recommended to all users who tend to print less often and may not fully value Pro3 Series’ new features.