Release notes

New requested features and debugging based on user feedback.

Texture

Added Texture Feature.

This feature can add custom texture on surfaces of the model. It can be enabled by clicking the Texture button from the top Menu Bar.

Slicing Preview:

The slicing settings related to Texture can be found under “Advanced Settings -> Texture”. Settings can also be added in the “Prepare to Slice” panel on the left side.

Users can download, upload, or share texture images in ideaMaker Library (https://www.ideamaker.io/texture.html).

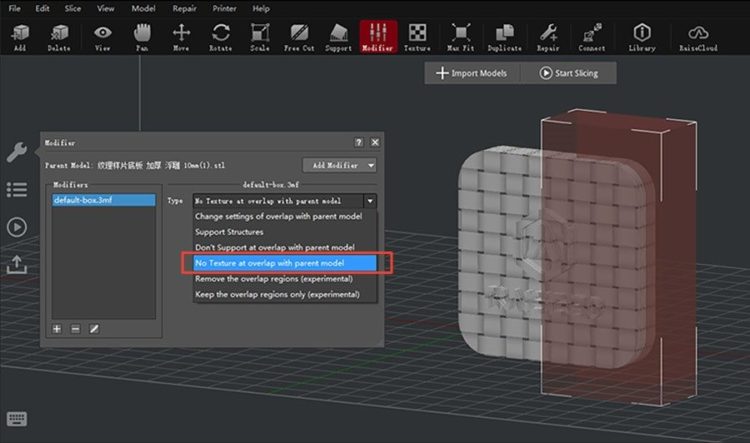

Texture Blocker

Added new Modifier types.

This feature can be used to remove the texture of a certain section where the blocker overlaps with the parent model. The texture blocker is a helpful feature any time the user wants to remove the texture in certain areas on the model.

Image to 3D Model

Added support for converting an imported image into a 3D model.

ideaMaker will ask the user to input the values of the model that need to be generated when importing an image into ideaMaker.

Image to Infills

Added support for Infill generated from image.

ideaMaker will convert the imported image to infill patterns. Users can select the pattern according to their needs. This feature is located at “Slice -> Custom Infill Pattern”.

Note: This feature may cause the size of the G-Code file to become larger, which will increase the total printing time.

Infill Density will be invalid while the Infill is customized Infill Pattern.

Belt 3D Printer

Added support to Belt 3D Printer.

Users can enable Belt Printer under “Printer Settings -> Advanced” and input the Gantry Angle inside.

The related slicing settings can be found at the left “Prepare to Slice” panel.

Settings can also be added from the “+” button at the bottom.

A Repetitions feature in the Project panel was added to adjust the quantity of duplicates of one model on the build plate.

The custom G-Code of Repetitions can be found and modified under “Advanced Settings > GCode > Repetition Gcode”.

Modifiers

Added support for selecting nozzle for Modifiers.

A certain section of the model will be printed by a different nozzle from the nozzle printing the rest of the model.

User Interface

1. Added the name of the model and sequence number into the G-Code file so that the Postprocess feature can be converted to be Code M486 to achieve the Cancel Object function.

a.Indicate the number of models in the beginning.

;TOTAL_NUM: 4

b.While printing non-model structures, such as Support, Wipe Wall, Wipe Tower, Skirt/Brim/Raft:

;PRINTING: NON-OBJECT

;PRINTING_ID: -1

c.While printing model structures, such as the first model <abc.stl>, the model ID will be started from 0.

;PRINTING: abc.stl

;PRINTING_ID: 0

d.Postprocess functions can be converted to be:

;TOTAL_NUM: 4 -> M486 T4

;PRINTING_ID: 1 -> M486 S1

;PRINTING_ID: -1 -> M486 S-1

2. Added Placeholders for printer dimensions.

3. Added the printed and remaining time in the G-Code file.

;PRINTING_TIME: 5372

;REMAINING_TIME: 623

Which means there are 5372 seconds already being used on printing and there are 623 seconds remaining.

During the sequential printing, the output time data will be related to the total print time, not the printing time of any individual model.

4. Added Shells Direction List option to control the printing directions of the shells to counterclockwise (CCW) or clockwise (CW).

5. In this version, the estimated filament usage will be calculated together with the total filament flow rate.

User Interface

1. Added a color to represent Ironing in the G-Code Preview.

2. Added an Orthographic video in the G-Code Preview.

3. Added the Swiss Franc into Currency.

4. Optimized the remote-control page and allow closing the print completion prompt to have access to some control of the printer and camera.

5. Added support for Spanish language. Language can be changed under “Preferences > Language”.

Bug Fixes

1. Fixed the issue that the modifiers will be lost when reloading the parent model.

2. Fixed the issue that the model file is not opened by double-click in Finder (macOS only).

3. Fixed the issue that the recover gcode is not generated properly.

4. Fixed the issue that the models may be lost the connection with the attached group sometimes.

5. Fixed the issue that the values are not sorted properly in the temperature list after the values in the list are modified.

6. Fixed the issue that the parameters are not updated in the Free Cut panel after the undo operation.

7. Fixed the issue that some layers may be missing during slicing.

8. Fixed the issue that some G-Code commands are parsed correctly and cause bad G-Code preview results.

9. Fixed the maximum changeable speed of the Wipe Tower and Wipe Wall speed.

10. Fixed the incorrect extruder color when displaying the G-Code files in the Duplication/Mirror Mode.

11. Fixed the issue that the adaptive layer height function does not work properly with some models.

12. Fixed the issue that the jerk values are incorrect when replacing exact settings values with the placeholders.

13. Fixed the issue that the gap filling exists even the top and down solid fill layers are zero.

14. Fixed the issue that the extrusion speed values are incorrectly output in the G-Code files.

15. Fixed the issue that the Modifiers are rendered incorrectly after repairing the parent model.

16. Fixed the issue that the Solid Fills will be missing in some conditions when setting the Infill Density to 100% and the option “Print Solid Fill in 100%” is enabled.