June 24, 2024

Reading Time: 15 Minutes

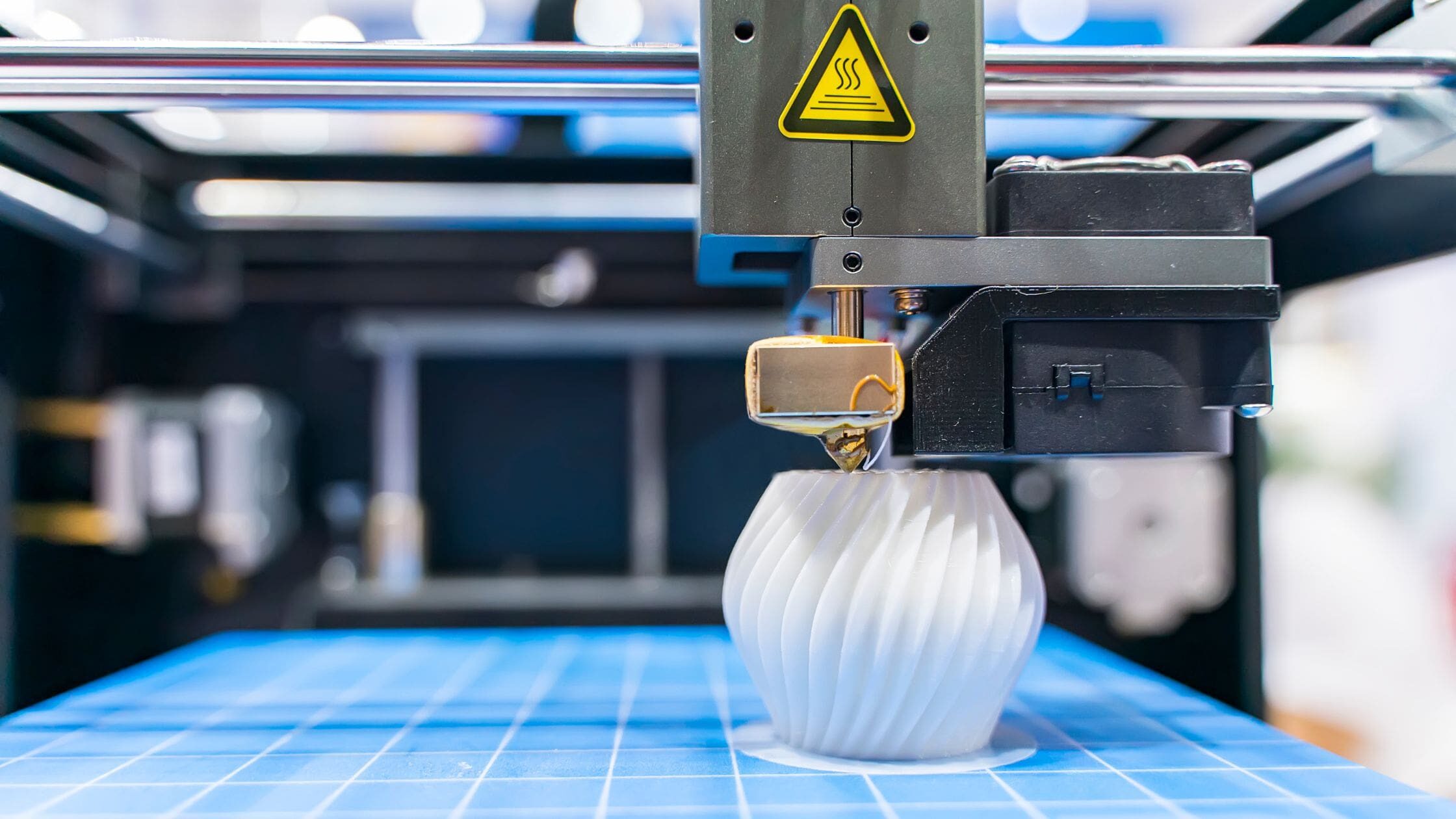

Exploring the realm of 3D printing, we often ponder, “How long does 3D printing take?” This question, seemingly straightforward, opens the door to an intricate world where technology meets creativity.

In this extensive guide, we’ll delve into the factors influencing 3D printing time and offer insights on how to optimize it.

How Long Does 3D Printing Take on Average?

Generally, a small and simple object might take about an hour to print, while more complex designs could take several hours or even days.

This range is mainly influenced by the object’s size, complexity, and the printer’s technology and capabilities.

How long does it take to 3D Print 1 Cubic Inch on Average?

Printing a cubic inch can typically take anywhere from 20 minutes to over an hour. This variation is largely dependent on the printer’s speed, the complexity of the design, and the chosen print settings like layer height and fill density.

What Are the Factors That Affect the Time It Takes to 3D Print a Part?

This 3d printing timeframe is not a simple estimation but a result of several interacting factors.

Each aspect of the additive manufacturing process plays a role, influencing the time from the moment you hit ‘print’ to when you hold the finished product in your hands.

Types of 3D Printing Technology

Different types of 3D printing technology have varying impacts on the time it takes to print an object. Each technology has its mechanisms and processes, affecting the overall speed and efficiency.

- Fused Filament Fabrication (FFF): This is one of the most common types of 3D printing. For instance, printing a standard-size vase in FFF could take about 4-6 hours, depending on the layer height and infill settings.

- Stereolithography (SLA): SLA printers use a laser to cure liquid resin. They are generally faster than FFF printers for small, detailed objects. A small, detailed figurine might take around 2-4 hours to print on an SLA printer.

- Selective Laser Sintering (SLS): SLS printers use a laser to sinter powder material. They are excellent for complex geometries but can be slower due to the sintering process. A complex, medium-sized part could take upwards of 10-12 hours to print.

3D Model

The foundation of any 3D printing project is the 3D model, a crucial factor in determining the printing time.

Let’s consider practical examples: printing a straightforward cube versus a detailed model of a car. The cube, with its simple geometry, might take only about an hour to print.

In contrast, the car model, with intricate details and complex structures, could require several hours or even a day. The complexity of the 3D model impacts the number of layers, the movements of the print head, and the overall printing time.

The design intricacy also affects the need for support structures, which can significantly increase the print time.

For instance, a model with overhanging parts or floating elements will require additional supports, adding more layers and complexity to the printing process.

The use of slicing software to prepare your model for printing also plays a role. The software’s settings for layer height, infill, and supports can either speed up or slow down the printing process.

In the realm of 3D printing, the choice of material is another determining factor. Materials such as PLA and ABS, commonly used in FFF printing, vary in their melting points and extrusion speeds, influencing the overall printing time.

Similarly, in SLA printing, the type of liquid resin used can affect the curing time under UV light, altering the printing speed.

Part Geometry

Part geometry is another significant aspect that determines the duration of 3D printing. The shape and complexity of the object you’re printing play a crucial role.

For example, printing a geometrically complex object like a lattice structure can be more time-consuming than a solid cube of the same volume due to the increased number of passes the print head must make.

Additionally, the print orientation and direction significantly influence the print time. Orienting a part to minimize the height (Z-axis) can reduce printing time, especially in technologies like FFF, where building up layers vertically is generally slower. For example, laying a figurine flat on the print bed instead of standing it up can reduce the print time significantly.

Part Size, Volume, and Dimensions

The size, volume, and dimensions of the part you intend to create are pivotal factors that directly influence the 3d printing time. It’s a matter of simple logic: the larger the object, the longer the printing process.

This is because larger objects require more layers, more material, and consequently, more time for the 3D printer to complete its task.

Let’s put this into perspective with practical examples:

- Small Objects: A simple keychain or a small chess piece, for instance, might take just 30 minutes to an hour to print on an FFF printer. These items, due to their small size, require fewer layers and less material.

- Medium-sized Objects: Consider a smartphone case or a medium-sized vase. These objects can take several hours, potentially up to 5-6 hours, depending on the complexity and the print quality desired.

- Large Objects: Now, if you’re printing something large, like a full-size helmet or a large decorative piece, the print time can extend to over 24 hours or even several days. The increased volume and surface area significantly add to the printing time.

The dimensions of your part also play a crucial role. For example, a tall, slender tower will take a different amount of time compared to a flat, wide landscape, even if they have the same volume.

The printer’s movements, the number of passes, and the changes in direction all vary based on the part’s shape, impacting the overall print time.

Filament Type

The type of filament you choose for your 3D printing project is not just about the aesthetics or physical properties of the finished product; it also affects how long the printing process will take.

Different filament materials behave differently under the printing conditions and have varying requirements that can either speed up or slow down the printing process.

For instance:

- PLA (Polylactic Acid): Being one of the most popular filaments due to its ease of use, PLA is generally faster to print. Its lower melting point allows for quicker layer adhesion, speeding up the printing process.

- ABS (Acrylonitrile Butadiene Styrene): ABS, known for its strength and durability, typically requires a higher temperature (more time to heat the bed), to print than PLA. This can mean a slower printing process, as the printer needs to maintain a higher temperature consistently.

- TPU (Thermoplastic Polyurethane): A flexible and rubber-like material, TPU can be more challenging and slower to print. Its flexibility requires slower print speeds to avoid errors and ensure accuracy in the final product.

- PVA: PVA print time is very similar to TPU as it is a little bit flexible but tends to grind down or wrap around items.

- Nylon: Tends to print slower due to the need for bonding and cooling

Different printers and their respective technologies also interact uniquely with these materials. For example, an FFF printer might handle PLA and ABS differently than a resin printer would handle liquid resin.

Each filament type also demands specific print bed temperatures, print speeds, and cooling times, all contributing to the duration of the printing process.

Layer Height

Layer height in 3D printing is a critical factor that significantly influences both the print quality and the printing time.

It’s akin to deciding the resolution of your print; lower layer heights yield finer details, but at the expense of increased printing time.

Let’s break this down with practical examples:

- Fine Detail Printing: If you’re printing a miniature with intricate details, like a small figurine, opting for a smaller layer height, say 0.1mm, is ideal. This will capture the fine details but will take considerably longer. A small figurine could take upwards of 6 hours to print with a high-resolution setting.

- Standard Printing: For standard prints like a phone holder or a simple vase, a layer height of around 0.2mm strikes a good balance between print quality and time. Such a print might take around 2-4 hours, depending on the size and complexity.

- Rapid Prototyping: When speed is more important than detail, such as in rapid prototyping of basic shapes, a layer height of 0.3mm or more can be used. This reduces printing time significantly but results in visible layer lines and less detail. For instance, a basic geometric shape might take just 1-2 hours to print.

3D Printing Settings and Profile

The settings and profile used in 3D printing significantly influence the print time. This includes layer height, print speed, infill density, and temperature settings.

Examples of how settings affect print time:

- Layer Height and Print Speed: A lower layer height increases detail but slows down the print. Conversely, a higher print speed can reduce time but may compromise on quality. For example, a decorative piece with a lower layer height might take around 8 hours, whereas increasing the layer height could reduce the time to 5 hours.

- Infill Density and Pattern: A higher infill density makes a stronger part but takes longer to print. For example, a functional part with high infill could take double the time to print compared to the same part with low infill.

- Temperature Settings: Optimal temperature settings for the material can also affect the print time. Incorrect temperatures can lead to print failures or the need for slower speeds, thus extending the print time.

- Support structures: They are critical for printing complex designs with overhangs or floating elements, directly influencing print time and post-processing duration. Adding supports can increase print time due to the extra material and layers needed. For instance, a model requiring extensive supports might take 10 hours to print, whereas a similar model designed to minimize support usage could reduce the print time to 7 hours. Additionally, removing supports adds to post-processing time, depending on the complexity and amount of support used.

Print Orientation and Direction

The orientation and direction of your 3D print significantly impact the overall printing time. This is because 3D printers typically print faster in the X and Y directions than in the Z (height) direction. Therefore, how you position your model on the print bed can either shorten or lengthen the printing process.

Practical Examples:

- Horizontal Orientation: Imagine printing a smartphone case. Orienting it horizontally on the print bed means it has a shorter Z-axis height, which can reduce the print time. This orientation might take around 2-3 hours to print, depending on the complexity and layer height.

- Vertical Orientation: If the same smartphone case is oriented vertically, it extends more in the Z-axis because of the support structures. This orientation can increase the print time significantly, possibly doubling it, because each layer takes longer to print as the height increases.

- Angled Orientation: For complex shapes like a propeller, an angled orientation can be a middle ground. It balances the height (Z-axis) and the surface area exposed in each layer, potentially reducing the support structures needed and optimizing the print time.

Do you want to create a decorative or practical object?

The purpose of your 3D print – whether it’s decorative or practical – can also influence the printing time. Decorative objects often require higher detail and quality, increasing the print time, while practical objects can be printed faster with less emphasis on intricate details.

Examples:

- Decorative Object: A detailed figurine, meant for display, requires high-quality settings for fine details, which increases the print time.

- Practical Object: A tool handle or a functional part, where the emphasis is on strength rather than detail, can be printed with thicker layers and faster speeds, reducing the print time significantly.

Print Head (Nozzle) Size

The size of the print head or nozzle is a crucial factor in 3D printing, influencing both the quality of the print and the time it takes to print an object. Different nozzle diameters can lead to variations in printing time due to the amount of material extruded per pass.

Examples with Different Nozzle Diameters:

- Large Nozzle (e.g., 0.6mm): Ideal for quickly printing larger objects. For instance, a basic vase with a large nozzle can be printed in about 2 hours, as it allows for the faster deposition of material.

- Standard Nozzle (e.g., 0.4mm): The most commonly used size, suitable for a balance of speed and detail. A standard-sized decorative box might take around 4 hours to print with this nozzle size.

- Small Nozzle (e.g., 0.2mm): Best for detailed prints. A small, detailed jewelry piece with a small nozzle could take over 6 hours due to the finer extrusion and slower print speed required for detailed work.

Quantity

The quantity of parts you’re printing plays a crucial role in determining the total print time.

This factor is often overlooked, but it’s essential to consider, especially when printing multiple items simultaneously or in succession.

Here is an example with a chess pieces:

- Single Part Printing: Printing a single item, like a chess piece, may take about 30 minutes. This is straightforward, as the printer focuses on one item at a time.

- Batch Printing: Suppose you decide to print an entire set of chess pieces at once. The print time will increase significantly, possibly to several hours, as the printer must create each layer of every piece before moving to the next layer. However, it’s still faster than printing each piece individually.

- Sequential Printing: If you choose to print the same set of chess pieces one after another, the total time could extend to a day or more. Although this method takes longer, it can reduce the risk of print failures affecting the entire batch. Also, keep in mind that sequential printing limits the height you can print at.

Infill Density and Pattern

Infill density and pattern are vital components in 3D printing that directly impact the strength, weight, and printing time of the final object.

Different Types of Infill Density and Patterns:

- Low Infill Density (e.g., 10-20%): Ideal for decorative items that don’t require much strength. Low infill density reduces print time and material usage. For instance, a decorative vase with 15% infill might take about 4 hours to print.

- Medium Infill Density (e.g., 40-60%): Suitable for functional items needing moderate strength. A phone stand with 50% infill could take about 6 hours to print.

- High Infill Density (e.g., 70-100%): Used for parts that require high strength and durability. A mechanical part with 90% infill might take upwards of 12 hours to print.

Infill Patterns such as grid, honeycomb, or triangles also affect print time and material usage. Honeycomb, for instance, offers high strength but takes longer to print compared to a simple grid pattern.

Post-processing

Post-processing in 3D printing is a significant phase that can greatly influence the total time taken from start to finish of a printing project. This process involves all the steps taken after the actual printing is complete, including cleaning, curing, sanding, painting, and assembling. The time and effort required for post-processing vary widely depending on the type of print and the desired finish.

Practical Examples:

- Simple Post-Processing: For a basic PLA print like a phone stand, post-processing might involve minimal efforts like removing support structures and light sanding. This could take approximately 30 minutes to an hour.

- Complex Post-Processing: For intricate models, like a detailed figurine, post-processing could include extensive cleaning of supports, detailed sanding, and painting. This process could extend to several hours or even days, depending on the level of detail and perfection desired.

FFF (Fused Filament Fabrication) 3D Prints

In FFF 3D printing, post-processing time varies based on the complexity and size of the print:

- Average Post-Processing Time: For a medium-sized FFF print, like a decorative vase, post-processing (including removal of supports and sanding) can take anywhere from 1 to 10 hours, even days on some occasions.

SLA (Stereolithography) 3D Prints

SLA prints require different post-processing steps, mainly because they use resin:

- Average Post-Processing Time: A typical SLA print, such as a small intricate jewelry piece, requires washing in isopropyl alcohol and curing under UV light. The average time for these processes can range from 1 to 2 hours.

SLS (Selective Laser Sintering) 3D Prints

SLS printing involves sintering powder material, which affects the post-processing required:

- Average Post-Processing Time: For SLS prints like a functional mechanical part, post-processing (including powder removal and possible dyeing) might take around 2 to 4 hours. Powder removal alone can take 1 hour on average.

DLP (Digital Light Processing) 3D Prints

DLP, similar to SLA, uses resin and UV light, impacting its post-processing time:

- Average Post-Processing Time: A standard DLP print, such as a dental model, typically needs thorough cleaning and UV curing, taking about 1 to 2 hours.

Finishing Touches for Your 3D Print

After the primary 3D printing and post-processing phases, finishing touches are what truly transform a print into a polished final product.

This stage is where creativity meets technical skill, allowing for enhancements that significantly improve the aesthetic and functional qualities of the print.

Depending on the complexity and desired outcome, finishing can range from a few hours to several days.

Metal Finishing

Metal finishing on 3D prints is typically pursued to improve the aesthetic appeal, durability, and sometimes the functional properties of a print. This process can include plating, polishing, or applying a patina to metal-like prints or metal-filled filaments.

- Average Timeframe: For a medium-sized object, such as a decorative metal-finished vase, the process might take anywhere from 2 to 5 days. This includes the time for surface preparation, application of the finish, and any curing or drying time required.

Painting

Painting is one of the most common methods of finishing a 3D print. It not only adds color but can also bring out finer details and textures. This process involves surface preparation, priming, painting, and sealing.

- Average Timeframe: The timeframe for painting a 3D print varies widely based on the size, complexity, and the number of layers or colors used. For instance, painting a small figurine might take 1 to 3 days, considering drying time between coats. Larger or more complex models, like a cosplay helmet, could take up to a week or more, especially if multiple colors or detailed work are involved.

How To Speed Up 3D Printing Times for Your Project?

Accelerating the 3D printing process is crucial for efficiency, especially in a fast-paced production environment. While it’s important to maintain a balance between speed and quality, there are several strategies you can employ to speed up your 3D printing projects without significantly compromising on the final output. Here are some practical tips:

- Optimize Printer Settings: Adjusting the printer settings for higher speed can reduce print time. However, be mindful that this might affect print quality. For instance, increasing the print speed on an FFF/FDM printers can cut down the printing time by 15-20%, but it may also lead to a rougher surface finish.

- Scale Down the Product: Reducing the size of the object can significantly decrease printing time. For example, printing a model at 80% of its original size could halve the printing time compared to its full-size counterpart.

- Batch Printing: Printing multiple parts of a model together can be time-efficient if your 3D printer has a large enough build volume. This approach eliminates the repeated setup times for individual prints. For instance, printing four small gears simultaneously could be twice as fast as printing them one after the other.

- Hire a 3D Printing Professional: For complex projects, consulting with a 3D printing expert can save time. They can offer insights into optimizing your print settings and choosing the right technology for your project. Their experience could reduce the trial and error process, thereby speeding up the overall project timeline.

- Use Larger Nozzle Sizes: Switching to a larger nozzle can expedite the entire process. For example, using a 0.6mm nozzle instead of a standard 0.4mm nozzle can reduce print time by up to 25%, especially for larger prints.

- Optimize Layer Height: Increasing the layer height can reduce print time. A layer height of 0.3mm will print faster than a finer layer height of 0.1mm, but with a trade-off in detail.

- Simplify Model Geometry: Simplifying the design of the model can reduce print time. For example, smoothing out intricate details on a decorative item can decrease the printing time significantly, as the printer head has fewer complex paths to follow.

- Choose Appropriate Infill Settings: Reducing the infill density and opting for simpler infill patterns can speed up printing. For functional parts where strength is not a primary concern, an infill density of 10-15% can reduce printing time substantially.

- Improve Slicing Software Efficiency: Utilizing efficient slicing software and optimizing its settings can reduce unnecessary movements of the print head, thus saving time. For instance, reducing the number of support structures in the slicing software can cut down on the print time for a complex model.

- Preheat the Print Bed: Preheating the print bed before starting the print can reduce the overall print time, especially for printers that take longer to heat up. This is particularly effective for materials like ABS, which require a higher bed temperature.

Conclusion

The journey of 3D printing is a complex interplay of various factors, each contributing to the total time it takes to transform a digital model into a tangible object.