[Detroit, April 8, 2025] – Raise3D, a global provider of flexible manufacturing solutions, proudly announces the launch of two groundbreaking 3D printing systems at Rapid TCT: the RMS220, the company’s first Selective Laser Sintering (SLS) solution, and the DF2+, an enhanced Digital Light Processing (DLP) resin printer building on the success of the original DF2.

These launches mark a significant step in Raise3D’s strategy to deliver end-to-end productivity transformation across multiple additive technologies, reinforcing its position in professional and industrial 3D printing after 10 years of commitment to innovation and customer success.

RMS220: Redefining Industrial SLS Efficiency and Cost Benchmark

As Raise3D’s first SLS system, the RMS220 is designed for batch production and delivers the following advantages to help enterprises reduce cost and increase efficiency:

Industrial-Grade Output with High Efficiency

The RMS220 delivers powerful daily production capabilities with up to 5kg of printed parts using PA12 material. Its large build volume of 220 × 220 × 350 mm supports the continuous manufacturing of large parts, making it ideal for batch production. With a high- speed printing rate of up to 2.2L/h at 20% fill density, it significantly improves production efficiency. The modular build chamber, paired with a quick 45-minute powder-change system, allows for flexible multi-material usage and minimizes downtime between jobs.

Affordable Scalability Built for Cost-effective Production with Long-term Value

The RMS220 is designed to low total cost of ownership (TCO) through hardware, material and system efficiencies. Powered by a high-performance 1064nm laser, the system unlocks access to a wide range of professional-grade materials right from launch — including PA12, PA11, and TPU — delivering exceptional versatility for advanced applications.

Its high throughput and quick turnaround reduce the per-part cost of production. Additionally, the system’s simple operation shortens the training and learning curve, and its easy-to-maintain design helps reduce labor involvement. The compact footprint further decreases the space and cost burden on production environments.

Printing Accuracy with Batch-to-batch Consistency at Industrial Scale

Precision and repeatability define the performance of the RMS220. It achieves ±0.2 mm dimensional accuracy and supports a minimum wall thickness of 0.5 mm (with PA11), enabling excellent detail control and minimizing warping. Equipped with a 75W high-power laser and a four-zone self-calibrating IR heating system, the printer ensures reliable part quality and consistent material properties across batches.

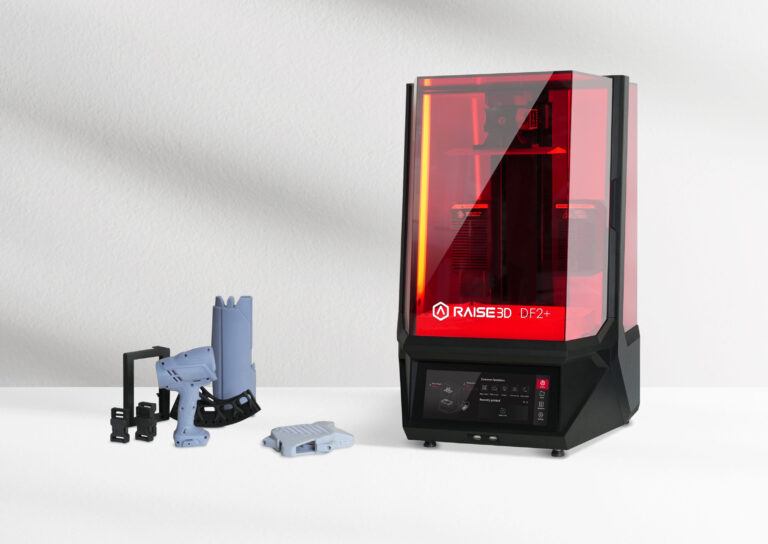

DF2+: Making Industrial DLP Printing More Accessible with Faster Speed and Expanded Resin Portfolio

After the launch of the DF2, the industry’s most cost-efficient resin DLP solution, Raise3D is now debuting the enhanced DF2+ printer, featuring a higher-power, long-lasting light engine, a 20% increase in printing speed, and broader compatibility with high-performance resins. These improvements expand its suitability for advanced manufacturing applications and, when combined with an intelligent post-processing workflow traceable via RFID, create a streamlined end-to-end production loop.

Raise3D’s Open Material Program continues to validate more resins from partners like Henkel and Forward AM, with the goal of introducing over 30 resins by Q2 2025—including ESD-safe, fire-retardant, high-temperature, medical-grade, flexible, clear, and high-impact materials—expanding use cases across a wide variety of industries.

Raise3D in collaboration with Würth Additive Group, a pioneer in digital inventory and supply chain innovation, has been showcasing the DF2+, the first 3D printer fully integrated with Würth Additive’s Digital Inventory Services (DIS) at AMUG 2025. This powerful combination enables secure, on-demand production, encrypted digital part distribution, and scalable additive manufacturing for industrial users worldwide.

Photo Credit: Würth Additive Group; Location: Greenwood, IN, Würth Additive Group Hanger (HQ)

Customer-Centric, Scalable Manufacturing Solutions: A Message from Edward Feng, CEO of Raise3D

As the manufacturing industry evolves, expectations for additive manufacturing have shifted from single-machine performance to end-to-end productivity transformation. Raise3D CEO Edward Feng commented: “To meet these needs, Raise3D takes a full-process approach—from deep integration of software, hardware, and materials to a comprehensive ecosystem spanning FFF, DLP, and SLS technologies. We focus on balancing performance, cost, and efficiency to drive innovation and ease production challenges.”

Both the RMS220 and DF2+ have already been validated by leading companies across a range of application scenarios, including custom jigs, functional prototypes, and low-volume end-use parts. During RAPID + TCT, Raise3D will host live equipment demonstrations, share application overviews, and display sample parts at Booth 3025.

New Product Availability

Raise3D is planning to begin shipping the RMS220 in the U.S. and European markets in Q4 2025, and the DF2+ is scheduled to start shipping in Q2.

Pricing

RMS220 Price Information (MSRP in the US will be determined after the tariffication is more settled):